3D Laser scanning for industrial plants - BIM

With the increase in size and complexity of industrial plants, it is essential to have high-speed, long-range, and high-precision 3D scanning equipment. In this sense, 3D laser scanning technology offers numerous benefits to engineers in charge of these projects.

By using digital 3D scanning, detailed information about the construction of plants can be obtained, allowing for complex modernizations and updates that fit the first time after installation. This significantly reduces the possibility of expensive engineering or calculation errors and avoids project delays.

In addition, 3D scanning facilitates design work and allows engineers to work highly efficiently. With it, 3D models and 2D drawings can be created to support specific projects, resulting in successful projects that are based on updated information and have minimal interference from clashes and other installation issues.

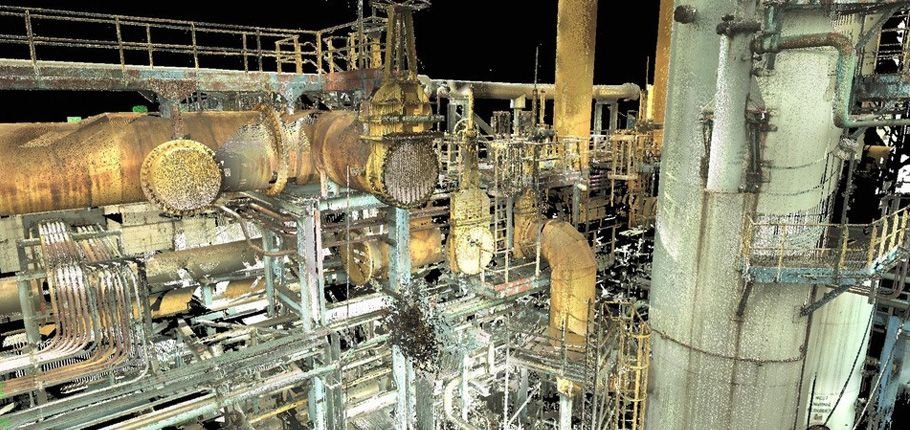

3D laser scanning is capable of accurately capturing everything within a given area, including structural steel, ducts, and other small elements such as lights and handrails. This creates a "digital twin" of the plant that allows engineers to take measurements, identify problems, and create precise and detailed solutions.

As for the process of 3D laser scanning of industrial plants, the steps are as follows:

- Identification of the scanning range area.

- Capture of a set of scans of the area of interest.

- Combination of the scans. Alignment of the scans with the coordinates of the plant.

- Production of a 3D CAD model or other desired deliverable (Autodesk Revit, Navisworks, Graphisoft Archicad, among others).

3D laser scanning works by capturing a 360-degree scan of all nearby equipment in a single scan. By combining multiple scans, sections of the plant can be captured in a single day. 3D scanners are capable of taking very precise measurements, resulting in accurate construction data.

In summary, 3D laser scanning is a fundamental technology for the planning, design, and construction of complex industrial plants. With it, costly errors can be avoided, work efficiency can be increased, and precise and detailed models can be produced to support specific projects.